Machinery equipment forms the backbone of industrial operations, encompassing a wide array of tools and machines essential for manufacturing, construction, agriculture, and more. The diversity within this sector contributes significantly to its competitive dynamics, fostering innovation, efficiency, and market growth.

Types of Machinery Equipment

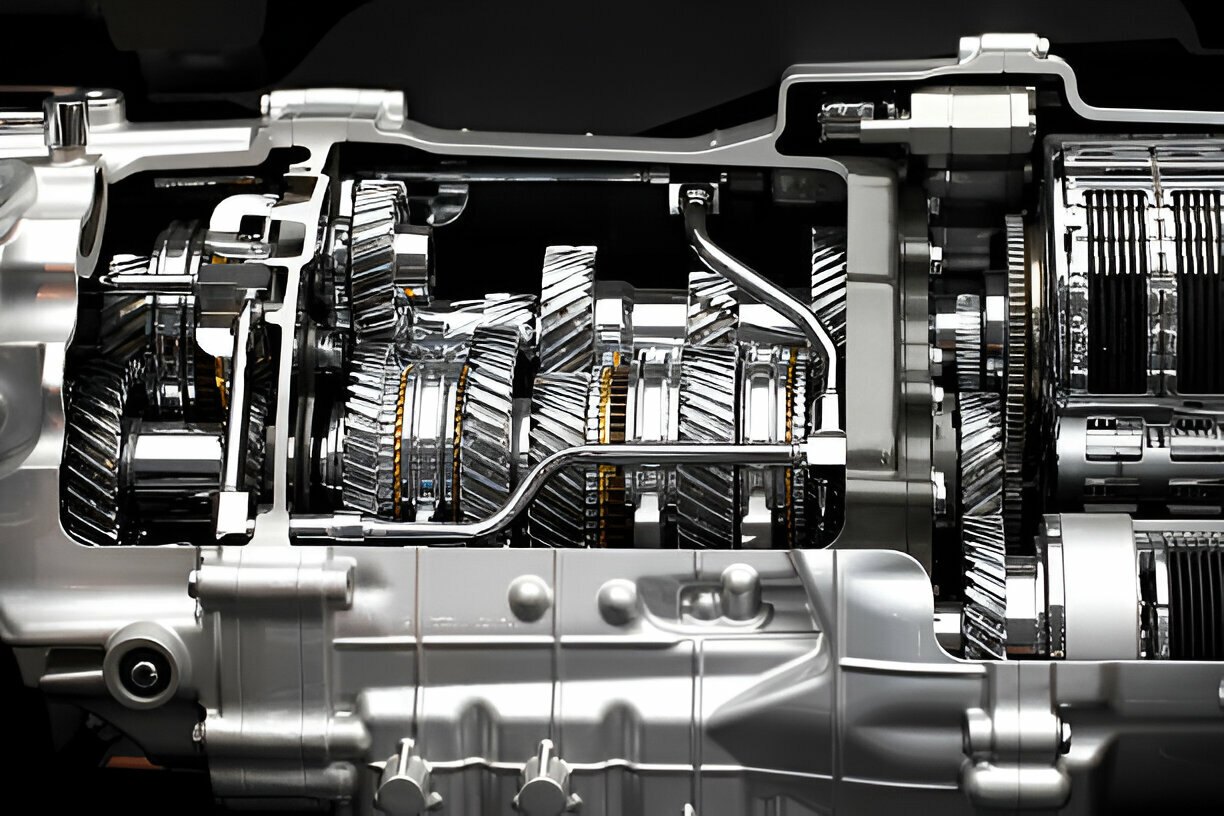

- CNC Machines: Computer Numerical Control (CNC) machines are pivotal in modern manufacturing. They include CNC milling machines, lathes, and routers that automate cutting, drilling, and shaping processes with precision and repeatability.

- Material Handling Equipment: This category includes forklifts, conveyors, cranes, and hoists used for transporting, storing, and handling materials in warehouses, factories, and construction sites. These machines improve logistics efficiency and reduce labor costs.

- Construction Machinery: Excavators, bulldozers, cranes, and concrete mixers are essential for infrastructure development. They perform tasks such as earthmoving, lifting heavy materials, and concrete mixing, accelerating construction timelines and improving project outcomes.

- Mining Equipment: Mining machinery like drills, loaders, and crushers are crucial for extracting minerals and ores from the earth. These machines enhance productivity and safety in mining operations by automating hazardous tasks and improving efficiency.

- Industrial Robots: Robots are revolutionizing manufacturing with their ability to perform complex tasks with speed and precision. They are used in assembly lines, welding operations, and material handling, increasing production throughput and quality.

- Farm Machinery: Tractors, combines, seeders, and irrigation systems are indispensable for modern agriculture. Agricultural machinery improves crop yields, reduces labor dependency, and optimizes farming practices.

Competitive Landscape

- Technological Advancements: Continuous innovation in machinery equipment, such as integration of IoT, AI, and automation, enhances operational efficiency and capabilities. Companies that adopt cutting-edge technologies gain a competitive edge by offering superior performance and reliability.

- Global Market Reach: Machinery equipment manufacturers compete globally to capture market share by offering tailored solutions that meet regional and industry-specific requirements. Strategic partnerships and alliances facilitate market expansion and customer retention.

- Quality and Reliability: Maintaining high standards of quality, reliability, and after-sales support is crucial for competitive advantage. Companies invest in research and development to improve product performance, durability, and customer satisfaction.

- Environmental Sustainability: Sustainable practices, including energy-efficient designs and eco-friendly materials, are increasingly important in machinery equipment. Manufacturers that prioritize sustainability gain favor with environmentally conscious consumers and regulatory bodies.

- Cost Competitiveness: Price competitiveness remains a key factor in the machinery equipment market. Companies optimize manufacturing processes, reduce production costs, and offer competitive pricing strategies to attract budget-conscious buyers.

In conclusion, the machinery equipment sector thrives on diversity, innovation, and competitiveness. Manufacturers that embrace technological advancements, prioritize quality and sustainability, and adapt to global market trends are well-positioned to lead and succeed in the dynamic machinery equipment industry.