Machinery equipment is fundamental to the operation of any manufacturing facility, regardless of the type of products being produced. These machines and tools are essential for automating processes, enhancing efficiency, ensuring precision, and maintaining consistent quality. The importance of machinery equipment cannot be overstated, as it impacts every aspect of production and overall business performance.

Enhancing Efficiency and Productivity

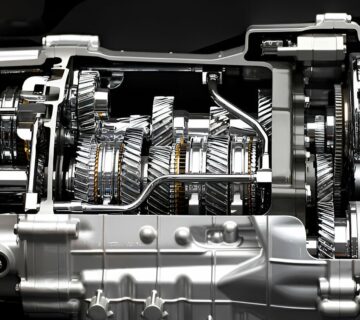

- Automation and Speed: Machinery equipment automates repetitive tasks, significantly speeding up production processes. Automated machines such as CNC mills, robotic arms, and assembly lines can work continuously without fatigue, drastically increasing output and reducing production time.

- Consistency and Precision: Advanced machinery ensures high precision and uniformity in product manufacturing. This consistency is crucial for maintaining product quality and meeting industry standards, which manual labor alone cannot achieve.

Reducing Operational Costs

- Labor Costs: By automating processes, machinery reduces the need for extensive manual labor, thereby lowering labor costs. Workers can be redirected to more strategic tasks that require human oversight and creativity.

- Material Efficiency: Machinery equipment is designed to optimize the use of materials, reducing waste and minimizing the cost of raw materials. Precise cutting, molding, and assembly processes lead to better resource utilization.

Improving Product Quality

- Precision Engineering: Machinery such as CNC machines and industrial robots provide unparalleled precision in manufacturing, ensuring that each product meets exact specifications. This level of accuracy is essential for industries where small deviations can lead to significant quality issues, such as in electronics or aerospace manufacturing.

- Quality Control: Automated inspection systems integrated with machinery equipment can detect defects and inconsistencies in real-time, ensuring that only high-quality products reach the market. This reduces the incidence of returns and enhances customer satisfaction.

Safety and Workplace Conditions

- Reduced Hazards: Machinery equipment can handle dangerous tasks that would pose a risk to human workers. For instance, heavy lifting, cutting, and exposure to hazardous substances are safer when managed by machines.

- Ergonomic Benefits: Automation reduces the physical strain on workers, leading to fewer workplace injuries and better overall health conditions. This results in a more motivated and productive workforce.

Scalability and Flexibility

- Adaptability: Modern machinery equipment can be reprogrammed or adjusted to handle different tasks and produce various products. This flexibility is crucial for manufacturers who need to adapt quickly to changing market demands.

- Scalability: As a business grows, machinery equipment can be scaled up to meet increased production demands without a proportional increase in labor costs. Investing in advanced machinery allows for seamless expansion and capacity building.

Competitive Advantage

- Innovation and Market Position: Companies that invest in state-of-the-art machinery equipment are often at the forefront of innovation. They can introduce new products faster, meet higher quality standards, and operate more efficiently than competitors relying on outdated technology.

- Cost Competitiveness: By optimizing production processes and reducing costs, businesses can offer competitive pricing in the market. This is particularly important in industries where price sensitivity is high.

Conclusion

Machinery equipment is indispensable for any manufacturing facility, regardless of the industry. It enhances efficiency, reduces costs, improves product quality, ensures workplace safety, and provides the flexibility needed to adapt to market changes. Investing in advanced machinery is not just about keeping up with the competition; it’s about setting the pace for innovation and excellence in manufacturing. For any factory aiming to thrive in today’s fast-paced and competitive environment, the integration of high-quality machinery equipment is a strategic imperative.